ABOUT US

Johnshock Global Co., Ltd is proficient in machining with many years of experience. We produce a variety of parts customized to customer specifications in many fields such as the automotive industry, aviation, the food industry and electronic engineering, etc.

In 2005, we started to develop woodwinds with professional musicians and have learned from them in the process. An accumulation of countless processing experiences and modernistic manufacturing technologies have helped us enter the music industry smoothly so far.

To persist in better acoustics and tone quality, we began a slow process of trial and error in our search to develop a truly ideal sax mouthpiece / flute headjoint.

Research & Development of the Saxophone Mouthpiece

The center of our mouthpiece concept was inspired by an extensive database. This not only took many years and efforts to build but also used proper science and experiments with a number of famously old mouthpieces of the golden-era.

Reverse Engineering Technology:

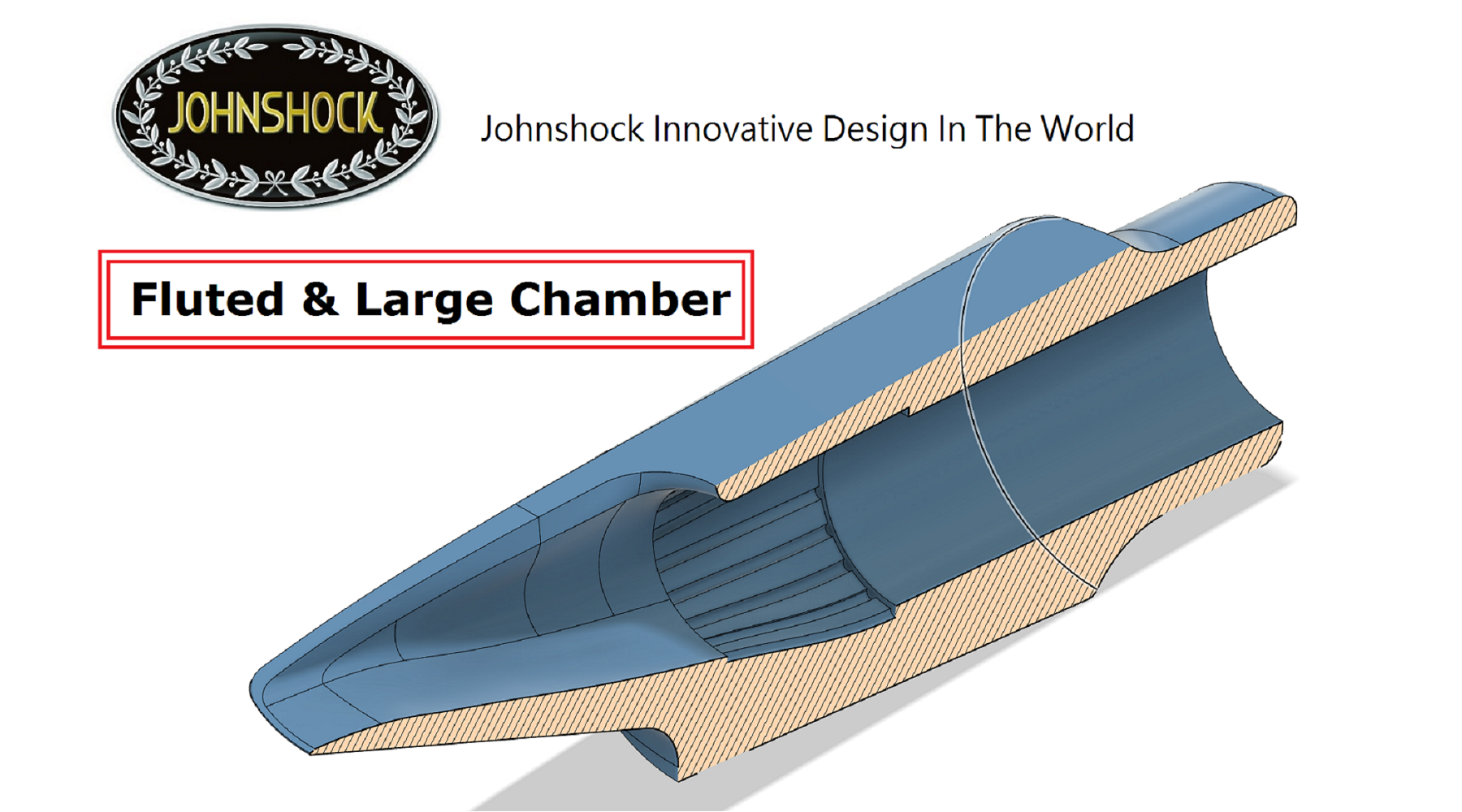

The white light non- contact 3D scanner is mainly combined one diffraction grating projector with two industrial CCD Camera. Using this high-tech equipment to digitize the dimensions of the mouthpiece. Furthermore using the 3D scan results in a very accurate and detailed STL file for our Computer Aided Design / Manufacturing (CAD, CAM) with intelligent software. In other words, we have totally collected the exterior and interior dimensions, such as body shape, beak angle, facing curve, baffle height, window and chamber size, etc in our database.

Material experiment:

Utilizing scientific experimentation like X-Ray Spectrometry to analyze the composition of the materials to uncover the elements and proportions that are influenced by the ring, depth and resonance of the metal. Additionally, we evaluated strength, ductility and specific gravity through mechanical and physical tests.

Referencing the exceptional vintage mouthpiece designs as our beginning point, we employed their successes but improved their flaws. Our mouthpiece would blend the natural resonance characteristics of the materials into our evolutionary designs to optimize the tonal efficiency and playability.

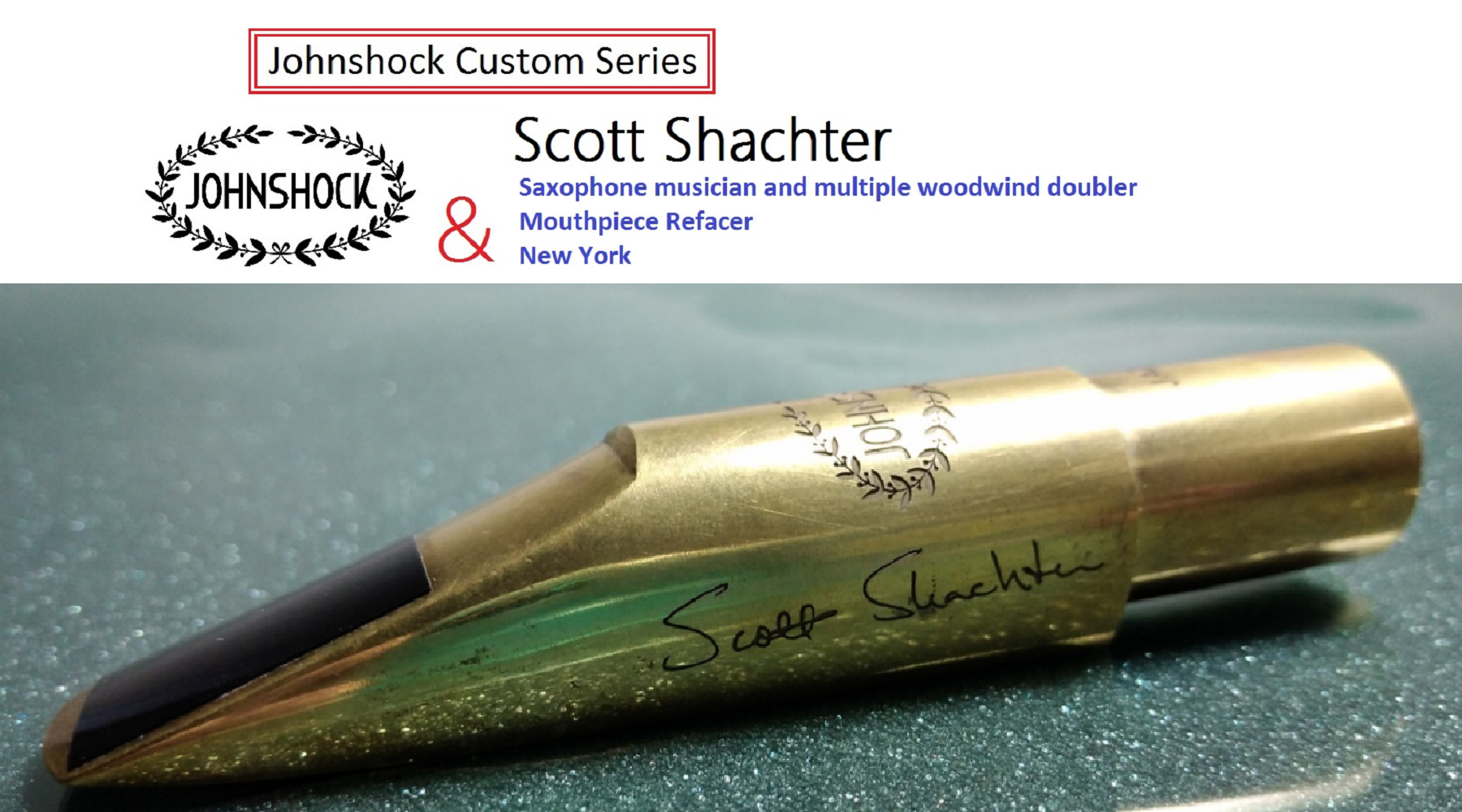

It is our belief that we can make a unique mouthpiece for professional musicians and players who want to play better and heartily enjoy it. We've gotten a lot of very positive evaluations from them.

Every mouthpiece is manufactured on the most precise Computer Numerical Controlled Lathes and High- Speed machining centers. Besides that they are play tested by experienced professionals and skilled artisans that do the final finishing work by hand to ensure that each one plays with the same standard.

All facings are a combination of geometric parabolas and computed curvatures, which result in the ultimate playing response throughout the whole range of the horn. Their uniformity is perfect every time since the CNC machining process we are good at.

Because of integrating specialized software programmer, varied progressive techniques, expert engineers and advanced equipment, we are able to achieve almost any design. Hence we will continue to develop the sax mouthpieces/flute headjoints to deliver what saxophonists/flutists covet and dream.